Power Engineering

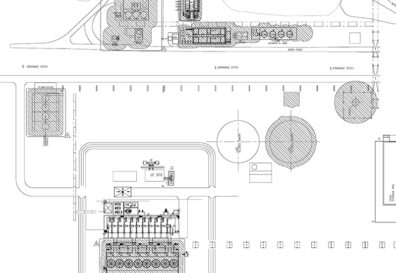

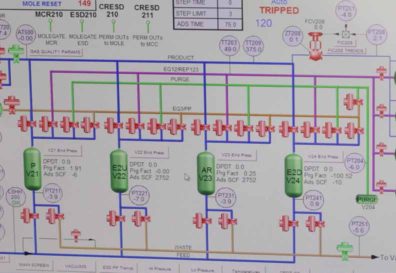

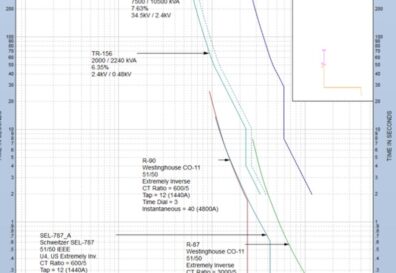

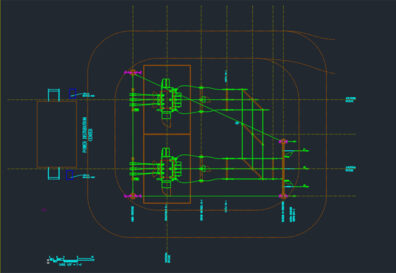

The global economy and infrastructure depend on efficient energy solutions to meet both global and international needs for good and services. At Professional Engineering Consultants (PEC), we understand this need and deliver services related to the operation, maintenance, and management of specialized industrial facilities including refineries, petrochemical plants, renewable plants, power plants, chemical plants, oil/gas facilities, and other process plants. From the initial planning to critical execution to construction, our engineering teams align with clients to successfully deliver projects that meet your requirements and strategic goals. Facilities we serve have processes that can create safety and environmental hazards if not designed, constructed, and operated properly. PEC takes great care to pay attention to details when designing these facilities.

We service a number of these markets that utilize process piping: renewable natural gas, chemical/refinery plants, combined heat and power, renewable diesel, ethanol plants, midstream facilities, fertilizer plants, hydrogen production, and paper and pulp mills. Partnering with the right engineering company that meets the ever-changing demands of the energy industry is a key factor in current and future growth. PEC has consistently been an engineering leader in finding solutions to meet the rigorous demands of our clients.

So Much More

Don’t get us wrong, we love our website, but there’s no way you can get the full PEC experience without talking to us or meeting us. Let’s set something up.