Services

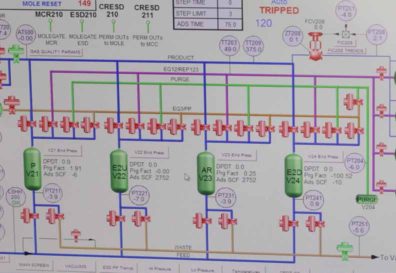

Power & Process Engineering

When so Much is on the Line

The Professional Engineering Consultants (PEC) power and process engineering team delivers highly responsive, timely services and high quality detailed documents related to the operation, maintenance and management of facilities that require a high degree of reliability and precision.

- Reliable

- Efficient

- Safe

- Diligent

Our Difference

What Sets PEC Apart

The PEC approach is client focused and success driven, designing with an eye towards innovation, schedule and budget. Our goals are your goals, and we will partner with you to create solutions specific to your facility.

Let’s Talk

We’re just a phone call or message away. Contact PEC headquarters at 316.262.2691 or visit our contact page to get started.